Engineering Manager

Dabur Egypt Limited

Total years of experience :20 years, 5 Months

Duties and Responsibilities:

•Modifying all the building to a green field one by introducing solar energy, solatube lighting, gas VAM chillers, chillers synchronization, led lamps, automation of building lights to automatic closure, air-conditioning, occupancy sensors and monitoring and BMS systems.

•Building capabilities and developing skills through FPR (First Person Responsibility), encouraging the technical team for KAIZEN’s program, developing operations in line with autonomous maintenance plan and recruiting skilled technicians in critical areas.

•Renewal for all the required government licenses for the factory as (Ministry of Health, construction license, health and safety compliance, power, operation license, civil defense approval, industrial registration).

•Strategical spare parts inventory adherence by standardizing and issuing SOP to ensure spares ordering by material codes and inventory, sustain and improve the activity of engineering spare warehouse, spares management (inventory & issuance of all critical spares in SAP and insure right procurement process. (Indent /PO/Approval/GRN) and ensuring no deviation from the standard process.

•Cost estimation for new projects & tenders, raising CAPEX’s process by ensuring all documents are ready including comparative and PO release in SAP for timely project execution and ensuring the projects adherence to cost, time and quality.

•Monitoring plant equipment to ensure optimal operation and reduction of planned/unplanned downtime and establish with operation, shutdown and start-up work programs to minimize the risks to the product, people and production losses ensuring GMP is followed.

•Systematically reviewing all lines, processes and utilities that are critical to the business and those where failure can have an unacceptable impact on safety, environment or compliance with the law by enforcing procedures, rules, and regulations.

•Verifying competitive pricing across a wide range of service industries to ensure cost saving and value engineering through research and experience such as but not limited to HVAC, plumbing, electrical structure, asphalt, concrete, flooring, roofing and general facility components.

•Creating and implementing plans to continuously improve site infrastructure, needs such as energy, water treatment, steam and all infrastructure services, contracts and contractors.

•Ensuring energy savings and optimization is in place as a key requirement for the facility operation.

•Defining standardized preventive maintenance process.

•Creating and implementing plans to continuously improve site infrastructure, needs such as energy, water, treatment, steam and all infrastructure services and contracts and contractors.

•Ensuring professional development of the technician’s team through training (especially new hires), transfer of information and know-how, individual reviews, performance and competencies evaluation, and progress action plans.

•Upgraded the capacity of liquid RAW material storage tanks within Dabur utility Area by adding new storage tank of capacity (80 Ton) including concrete base, day use storage tank, loading/unloading lobe pump, load cell, piping network and interface. The project is done through:

•Providing initial layout, design and cost estimate leading to 2.5M LE

•Preparing high level estimates, schedule and design basis documents allowing for quicker, more effective decision making and execution.

•Government licensing and approvals for the new project, construction license and civil defense approval.

•Enhanced the Production by adding new 4 Ton Mixer with side kettle. This was done through:

•Value engineering, equipment installation in coordination with manufacturer.

•Visibility study (IRR), cost estimation for new projects raising CAPEX’s and ensuring the projects adherence to cost, time and quality.

•Managing turnkey expansion project within the building including civil work, MEP and line relocation through several contractors, and ensuring coordination of Engineering, activities and cost estimate leading to 15M LE.

•Engineering drawings, layouts review, approving and coordination with different trades before work startup and ensuring the best solutions are approached during installations and erection.

•Cost estimation for new projects & tenders, raising CAPEX’s and ensuring the projects adherence to cost, time and quality.

•Selection & supervision of suppliers, vendors & subcontractors based on specs and standards.

•Risk analysis for new projects utilizing the lessons learned.

•Preparing material, cost and timing estimates, reports both executive and top management reports introducing the project KPI’s, cash flow, manpower histograms.

•Invoices, BOQ checking and approving for company vendors and suppliers.

•Erection works follow up, prioritizing planning & monitoring to ensure the projects is carried out according to time schedule in compliance with the plant requirements and standards.

•Value engineering, equipment installation in coordination with the manufacturer.

•Contracts administration, variation orders, purchase orders formulation & negotiation till signature.

•Following up with the equipment manufacturer ensuring the required quality standards and following up on materials, equipment supplies and FAT (Factory Acceptance Test).

L'Oréal (Cosmetics, More than 30, 000 employees

Duties and Responsibilities:

•Apply SHE regulations in line with the Group policy.

•Organize the day-to-day operations, facility building and raw materials reception following the regulations and prevention plan.

•Take part in working groups, improvement committees and transverse projects to help optimize site processes.

•Draw up prevention plans for service providers and sub-contractors.

•Manage the facility building and utilities distribution for the site (HVAC system, Heating, hot water, soft water, compressed air, ….).

•Responsible for the Maintenance and Projects expenses, investment, and manpower budgets.

•Supervise the Maintenance team, Projects team and sub-contractors team.

•Coordinate maintenance and site projects with support from outside service providers and contractors.

•Deal with other departments, with any anomalies in the supply of utilities; minimize all malfunctioning of the installations or of the site’s infrastructure.

•Participate in major factory projects as an expert (buildings, electricity, thermal engineering, fluid dynamics, etc.)

Achievements:

•Reduced energy consumption by 21% within the first-year utilizing the cost reduction initiative.

•Implementing and execution BMS and Energy control system for the whole building.

L'Oréal (Cosmetics, More than 30, 000 employees

the Factory Acceptance Test (FAT) for the new equipment and machinery at the suppliers’ premises “European Region”.

•Led and identified the allocation of equipment and machinery during the plant construction phase, specified the utility dropping of each and coordinated their installation.

•Managed technical plan to carry out the production target with the highest possible yield while respecting quality, safety, hygiene, environment regulations and performance objectives.

•Hired the technical team and set up the organizational structure, evaluation KPIs and team development plan.

•Provided a service and repair programs to assist the production team optimizing the performance level and keeping downtime to the minimum level.

•Implemented management fundamentals (day-to-day team management, held meetings, regular presentation of objectives and results to teams, top-down and bottom-up communication, etc. …).

•Ensure that product launches are effective by assessing needs for equipment/lines, in conformity with the launch schedule (participate in packaging development meetings).

•Managed investments in production equipment and its maintenance according to requirements and respecting Group manufacturing rules.

Achievements:

•Contributed in the factory startup, ramping up and day-to-day operation to align with L’Oréal’s standards and safety regulations.

•Had a workforce mission to South Africa for 3 months supporting the technical team in installing a new production line including Utility dropping and layout.

Hi-Pack for Packing Materials (ARMA Group) (Packaging and Containers, More than 10, 000 employees

Duties and Responsibilities:

•Directed maintenance activities for utility systems providing continuous supply of chilled water and compressed air required for operations.

•Managed maintenance, repair and troubleshooting of mechanical equipment including compressors, pumps, chillier, boilers, steam piping and work as

technical supervision by applying preventive maintenance, periodic checkup, changing components which have a certain life time, and for sudden failure parts, applied corrective maintenance.

•Completed supervision for production machines operation, finding out ways to fulfill production targets and maintaining high quality productivity.

Duties and Responsibilities:

•Responsible of all utilities and machinery overhauling, applying preventive maintenance.

•Mechanical and Electrical (power and control) installation of cutting gang saw and polishing machines, machinery under supervision of supplier’s installation experts (Italy)

Trainings:

•Actuation systems:

•Pneumatic & Electro-Pneumatic systems and Hydraulic power systems control.

•Valves, Actuators, Construction and Reading of its Circuits and connections.

•PLC (Programmable Logic Controllers):

•Ladder diagram and Logic blocks (step 5).

•Microprocessors and interfacing.

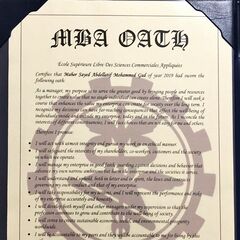

MBA : Certified

: