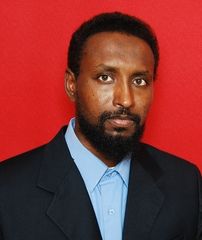

Senior Mechanical Engineer

Worley Parsons

Total years of experience :18 years, 0 Months

Riyadh PP10 Combined Cycle Power Plant MW)

Power Plant consist 40*60MW GE Gas Turbine, 40 HRSG& 10*120MW GE Steam Turbine

Carrying out inspection for contractor installation

works associated with (Steam Turbines, HRSGs& their related rotating equipment’s) and verify works compliance to specification & standard QA/QC requirements.

Issuing erection, installation works and material acceptance reports.

Handling QA/QC activities covering ITP, RFIW, RFIM and Method of Statement & related installation drawings.

Preparing punch lists for Steam Turbines installation.

Witnessing lube oil flushing and give final acceptance and pre and final alignment for STG

Looking after lift oil adjustment and seal steam commissioning.

Carrying out function test for the major system (Lube Oil, Control System…)

Turning gear engage test, STG rotor float test, load rejection test, over speed test and exhaust water spry water test.

Hydromiling for (HP&LP) pipe downstream of MSCV& ACV.

PerformTOP activity.

Analysing the HP pump (BFWP) problem.

Riyadh PP12 Combined Cycle Power Plant 2750MW) in Saudi Arabia .Power Plant consist 8*171MW (7FA.05) Gas Turbine, 8 HRSG& 2*350MW Steam Turbine.

Responsibilities:

Carrying out inspection for contractor installation works associated with (Steam Turbines, HRSGs& their related rotating equipment’s) and verify works compliance to specification & standard QA/QC requirements.

Issuing erection, installation works and material acceptance reports.

Handling QA/QC activities covering ITP, RFIW, RFIM and Method of Statement & related installation drawings.

Preparing punch lists for Steam Turbines installation.

Witnessing lube oil flushing and give final acceptance and pre and final alignment for STG

Looking after lift oil adjustment and seal steam commissioning.

Carrying out function test for the major system (Lube Oil, Control System…)

Turning gear engage test, STG rotor float test, load rejection test, over speed test and exhaust water spry water test.

Hydromiling for (HP&LP) pipe downstream of MSCV& ACV.

PerformTOP activity.

Analysing the HP pump (BFWP) problem

Garry 4Sponge Cock Fired Power Plant 110 MW, Khartoum North

Executed maintenance activities depending on the maintenance strategic plane (PM, CM); performed proactive maintenance as result of CBM program and updated equipment base line after major overall maintenance.

Prepared Root Cause Analysis for equipment’s force outage and monitored status of critical consumable material.

Steamed Turbine Mini & Major overall maintenance.

Managed Steam Turbine maintenance staff.

Classified equipment’s maintenance as critical, essential or general purpose.

Issued maintenance (Daily, Monthly and Annual) report.

Project Implementation Department.

Garry 4 Sponge Cock Fired Power Plant 110 MW, Khartoum North, Consultant : LI

(Power Plant consist of: 2 Steam Turbines, 7 Heat Exchangers, and 4 variable speed, multi stage Boiler Feed Pumps, Cooling Tower and Oil system)

Main activities and responsibilities:

Responsibilities include design review, installation supervision and commissioning.

Design Reviewing Activities

Reviews and endorses conceptual designs and respond to specifications modification requests.

Review mass & heat balance calculation for steam cycle in different load capacities.

Review P&IDs for all plant systems.

Giving remarks and recommendations on final Control Concept for normal operation, protection philosophy and emergency procedures.

Reviewing Trip Matrix and alarming philosophy according to manufacturer recommendations and operational scenarios.

Piping works authentication which include:

Pipes routs and specifications to reduce head losses.

Selection of suitable supports and hangers distribution to absorb hydraulic and static forces.

Piping protection by establishing relive and drainage systems.

Pumps selection compatible with pumps characteristic curves and system curves best efficiency points, along with pumps protection (NPSH, SHUT OFF RUNING, and RUN OFF).

Evaluates / endorses modification requests involving a wide variety of mechanical systems

Installation and Erection Activities

Issued or ratify modifications of original design according to site condition.

Receiving the equipment with corresponding documents on site and checking its validity.

Following up the erection and installation of the equipment and insure compliance with technical specifications.

Testing & commissioning

Wittiness FAT for Variable Speed Multi stage pumps and giving final acceptance of results.

Pre-testing acceptance for all related equipment and systems including pipe flushing, turbine governing system test, steam turbine loading test, vacuum leakage test, hydrostatic pressure test, etc.

Final acceptance tests including Steam Turbine over speed test, load rejection test Steam Turbine performance test.

Editing steam turbine monthly progress reported to the site manager

Managing 4 junior engineering staff.

Power Plant consisted of: 410MW, 2 Steam Turbine Engines, 4 Gas Turbine Engines, 4 Heat Recovery Systems, Heat Exchangers, Light Diesel Tanks, LPG Tanks, Fans, Pumps, Valves, etc)

Main activities and responsibilities

Supervised the start up and shutdown for the units.

Participate in Commissioning of combined cycle (Two gas Turbine+ Two HRSG + one

Steam turbine)

Monitor gas Turbine performance

In charge of Gas Turbine commissioning after CI and HGPI.

Prepared the daily efficiency report.

Prepare training plans for shift staff according to job requirements.

Issuing work order to maintenance section upon equipment failure/malfunctioning and insure safe execution of maintenance works by applying Tag-out/Lock-out procedures.

Prepare incident/trip reports and provide recommendations where required.

Managing 2 junior engineers and 11 technicians members of staff.

Power Plant consisted of: 410MV, 2 Steam Turbine Engines, 4 Gas Turbine Engines, 4 Heat Recovery Systems, Heat Exchangers, Light Diesel Tanks, LPG Tanks, Fans, Pumps and Valves)

Installation and Erection Activities

Testing & commissioning

o Witnessed Pre-testing for acceptance and write report to the senior Engineer for following item:

o Lube oil flow and flushing -Steam turbine governor static test, shaft lifting test, cooling tower fans running test, etc.

Executed preventive and corrective maintenance for the Steam Turbine and its ancillary plant equipment’s as follow:

o Pumps (Centrifugal-Axial-Screw-HP Multi-Stage) coupling alignment using dial gauges, bearing, impeller, shaft, mechanical seal replacement.

o Cooling tower Fans blades angle adjusting and alignment of fan shafts with gearbox coupling.

o River Side Plant include(dosing pumps-pre-settler tank rotary rack- a complex of pump floating intakes water barge- submersible forwarding pump.

o Demineralization plant (Anion- Cation - Mixed beds-sand filter).

Executing major overhaul maintenance for :

o Hp multi stage feed water feed water pump (KSB) 246.24t/hr, 134 bar with variable speed hydraulic coupling (VOITH).

o Cooling Water pumps double suction 9132m3/hr, 2.8 bar.

o Vertical & horizontal condensate extraction pumps 214.4m3/hr, 12.8bar.

o Axial flow Intake pumps 280 m3/hr, 2.3 bar.

o Submersible Forwarding pumps 360m3/hr, 3bar

o Valves and Heat exchangers.

Time schedule and resource planning for ST Major overhaul.

o Carried out all necessary improvement needed in the power plant so as to increase efficiency and reliability of steam turbine and its related ancillary

o Issued Daily &Monthly maintenance report to the Steam Turbine maintenance Manager.