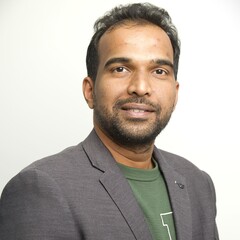

Site Quality Manager

M. H. Alshaya Company - Saudi Arabia

Total years of experience :15 years, 4 Months

Lead the site in developing a culture where product quality is seen as central to our operation and products are made right the first time. The ambassador of quality for the site provides confidence to customers (Starbucks) that high-quality consistent product is delivered to the stores every time. Creating a strategy for the site's quality goals and KPIs that are in accordance with the overall business strategy. Manage and support the quality team to provide comprehensive quality control support to the operations team. Support the team in ensuring maximum utilization of operational staff and equipment in achieving KPIs and optimal line efficiency within the company safety, quality & environmental policies. Encourage and develop a culture where Health and Safety is first and foremost with every task carried out, ensuring the safety of those in their control. Encourage the utmost degree of compliance with all audits, including HACCP, GMP, H&S, etc. To promote continuous improvement, comprehend, analyze, and focus on industry "best practices." Develop finished product specifications for all existing products and any NPD launches, clearly identifying acceptable and unacceptable standards ensuring these are achievable in full-scale production Conducting Starbucks store audits in KSA along with the Marketing team to ensure the products are displayed and served as per the premium standard expected by customers.

Functional head of 2 factories of Americana KSA Operations producing IQF/Chilled Meat and Chicken products with direct responsibility of quality functions - supplier approvals, production facility, logistics, QSR, customer and consumer management.

Lead the quality team to organize, manage, control, and improve the activities of food safety and quality to ensure timely and accurate fulfillment of business needs in compliance with the food safety and quality KPIs.

Determine training plans for the factory team according to job and business requirements.

Estimate, prepare, and agree on food safety and quality budget with operations management.

Confers with concerned departments regarding quality parameters of NPDs and products on market to rectify any quality issues

Functional Quality head in production facilities producing bakery, dairy and juice products with direct responsibility for the process, laboratory, hygiene, audits, warehouses, and pest control.

Member of the senior management team for the development and implementation of goals, objectives, policies and procedures for the production facility that satisfies customer and regulatory requirements of Almarai.

Coordinating with Corporate Group Quality team to implement “world’s best practices” in plants

Implementation and Management of the Integrated Management System (ISO9001, ISO22000 and HACCP)

Developing 5yr financial and master plans for QA and utilizing processes, tools and guidelines for overseeing and optimizing the costs and budgets for QA services

Spearheading the FSSC 22000 V.5 transition for the site.

Productivity monitoring and management, as evidenced by active work planning and measurement of each employee’s output and performance in close coordination with the human resources department.

Responsible for site-level coordination with more than 50 suppliers (overseas and KSA) delivering 100+ ingredients and 40+ packing materials to ensure material meets Almarai standards

Managing multifunctional QA team consisting of QA Manager, Continuous Improvement Manager, Asst. QA Manager, Team Managers, Team Leaders, QA Technicians and other workforce.

Functional Quality head 2 production facilities producing bakery products with direct responsibility of process, laboratory, hygiene, audits, warehouses and pest control.

Implementation and Management of the Integrated Management System (ISO9001, ISO22000 and HACCP) leading to certification and working with Operations, Engineering and Process departments ensuring that all food safety criteria are followed

Lead auditor of ISO 9001:2015, ISO 22000:2018, AIBI and HACCP Team Leader.

Functioning with R&D and regulatory teams to ensure highly disciplined compliance with products and process quality parameters and legal standards

Ensure the QA activities are done in compliance with Almarai HSS policy; to monitor and reduce the LTIFR of department

Managing multifunctional QA team consisting of Continuous Improvement Manager, Asst. QA Manager, Team Managers, Team Leaders, QA Technicians and other workforce.

Managing the responsibility of supervising site QA activities and provide clear objectives for

daily operations, deputizing for QA Manager, as required.

Directly responsible for QA activities in Production floor with 12 high speed lines,

Inbound/Outbound Warehouses and Laboratory

Reviewing and approving consumer complaint investigation reports, monitoring and analyzing

consumer CPM trends.

Working closely with human resources departments to develop performance improvement

programs and appraisals for employees

To ensure effective and appropriate corrective action are implemented for non-conformance

and quality deviations, including appropriate communication and discussion with senior

management on implementing agreed corrective actions.

Lead Auditor for AIB, ISO 22000, and Hygiene/GMP audits in production lines

Reviewing validation reports of new line installations encompassing product quality and food

safety

Managing 3rd party pest control team in the site ensuring 0% pest related issues in the

production premises.

Job includes management of systems applied for the continuous improvement of Food Safety

Standards and Quality standards in Six Almarai Bakery plants across Riyadh and Jeddah,

utilizing tools like Internal audits, Q Pulse Module, Customer Complaint Investigation and

trend analysis

Internal Auditor for ISO 22000, ISO 9001 and AIB. Team Member of HACCP program.

To maintain database for consumer, Sales generated Complaints, documentations, CAPA

implementations and verifications. Training of DP coordinator for updating the database.

Provide trends as per specific requirements from higher management.

Monitoring the CPM trends of the finished products and keeping the KPI value under target

by investigating root cause, corrective and preventive action in production line for continuous

improvement and high standard of customer satisfaction.

Preparing presentations for Quality in monthly MRM’s. Circulating monthly and yearly reports

to Divisional Quality Manager and higher management

First Person Responsible (FPR) for the entire Water Treatment System and Syrup preparation

of plant and maintaining Syrup and Water Quality within PepsiCo standards.

Assures Quality of PET Bottle, Line Glass bottle line (GRB) and packaged drinking water line -

Aquafina, in PepsiCo Plant.

Responsible for syrup planning according to the plan circulated by demand planner from

Market Unit.

Planning sanitation schedules and validation of Water treatment plant, syrup plant and

finished products based on micro test results.

To attain beyond targets of various KPIs like Conc. Yield, Sugar Yield, Sugar Delta, Water

Number and C&C (Cost Per Case of Chemicals & Consumables).

Responsible for man management on the line with a man power of 20, consisting of

technicians and operators.

To assist Q.C Team in conducting various Audits like- AIB, HACCP, GQA, ISO etc. and to train

operators on various food safety systems and other quality parameters.

Physical, Chemical and Microbiological Analysis of milk and milk products.

Microbiological analysis of process water via TBC, Pseudomonas, total coliform and E coli by

membrane filtration and validation of CIP process.

Monitoring the packing quality and specifications of finished products

Manage the plant to produce quality products in the most effective, safe, and hygienic way on

daily basis.

Raw material quality monitoring and final product analysis and maintaining the HACCP system

Assisted in microbiology related projects on Bio fertilizer, bioethanol production and bio

control agents.

Made carrier based and liquid bio fertilizers of Pseudomonas, Acetobaceter and Azospirillum.

Work with Research and Development team in India government funded research projects.

Microbial analysis of Spices and spice products via total plate count, yeast and mold,

Salmonella, Listeria, Clostridium, Bacillus, E.coli, Enterobacteriaceae and coliforms in

accordance with internationally accepted USFDA and BAM procedures.

Maintenance and calibration of equipment’s in microbiology lab including Sophisticated

Automated instrument namely VIDAS (Vitec Immuno Detected Assay System) for the

detection and enumeration of pathogens like Salmonella, E. coli and Listeria which works

under the immunological principle ELFA.

Maintaining the ISO 14001:2004 & ISO/IEC 17025:2005 specifications of the lab.

with 66% marks.

with 82% marks